Infrared filters are transforming gas detection technology. They make measuring carbon monoxide (CO) and other gases accurate and dependable. These special optical parts pick out certain light wavelengths. This boosts sensitivity and cuts down on distractions from the environment. This article explains how infrared filters work, their key role in Non-Dispersive Infrared (NDIR) sensors, and their benefits in industries like factories, environmental checks, and medical tools. Learn how Bodian’s cutting-edge infrared filter solutions improve CO detection across many fields. Also, explore new trends shaping the future of gas analysis technology.

The Role of Infrared Filters in Gas Detection Technology

How Do Infrared Filters Work?

Infrared filters are vital in gas detection systems. They let specific light wavelengths pass through while stopping others. These filters are carefully made using advanced equipments for high accuracy. Infrared filters are sensitive parts that use infrared optics. Their tiny “lenses” hold great power. They focus on the exact light regions needed to detect gases like carbon monoxide (CO).

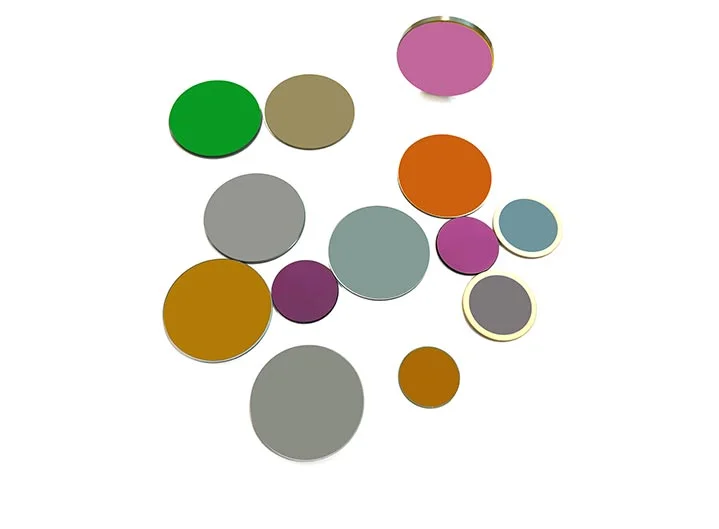

These filters come in different types for various needs. For example, our company offers infrared narrowband filters, infrared broadband filters, infrared long pass filters, infrared short pass filters, and infrared anti-reflection filters. Each type is built to meet specific demands. This makes gas detection devices more accurate and reliable.

Why Is Wavelength Selection Important for CO Detection?

CO detection depends on finding unique absorption bands of carbon monoxide molecules. These bands are in the mid-infrared part of the light spectrum. Infrared filters ensure only the right wavelengths for CO’s absorption reach the detector. They block unwanted wavelengths that could cause confusion or noise.

This careful selection reduces interference from other gases or environmental factors. By focusing only on CO’s absorption spectrum, gas analyzers give precise readings, even in tough settings.

How Can Infrared Filters Boost Signal Clarity?

In gas detection, a clear signal with low noise is critical for trustworthy results. Infrared filters help by cutting out background noise from stray light or other gases’ overlapping signals. They isolate specific wavelengths, so the detected signals are strong and clear.

Also, special coatings on these filters reduce reflection and increase light transmission at the right wavelengths. This makes gas analyzers more sensitive and accurate.

The Mechanism of CO Gas Detection Using Infrared Technology

What Are Carbon Monoxide’s Absorption Traits?

Carbon monoxide has unique absorption traits in the mid-infrared region because of its molecular makeup. When hit with infrared light at certain wavelengths, CO molecules soak up energy. This lowers the light’s strength. This effect is the basis for detecting and measuring CO levels in the air.

Infrared filters are key here. They allow only the wavelengths tied to CO absorption to reach the detector while blocking others.

How Do Non-Dispersive Infrared (NDIR) Sensors Work?

Non-dispersive infrared (NDIR) sensors are popular for CO detection because they are efficient and reliable. These sensors have an optical path with an IR source, a sample chamber, an infrared filter, and a detector. The IR source sends out light that passes through the sample chamber holding the gas.

The infrared filter plays a big role. It ensures only wavelengths matching CO’s absorption spectrum reach the detector. A drop in light strength at these wavelengths shows the presence and amount of carbon monoxide.

What Challenges Exist in CO Detection?

Detecting carbon monoxide accurately is tough. Issues include interference from other gases, changing environments, and weak signals at low CO levels. Infrared filters tackle these problems by:

Improving selectivity with precise wavelength isolation.

Reducing interference from other gases or outside light.

Strengthening signals by optimizing light transmission.

Environmental detectors, used in areas like environmental protection, depend on this method.

Advantages of Using Infrared Filters in CO Gas Analyzers

How Do They Improve Sensitivity and Accuracy?

Infrared filters boost sensitivity by focusing on target-specific wavelengths. This cuts out noise from unrelated light regions. As a result, measurements are more accurate, even at low CO levels.

Special designs, like narrowband filters, focus on very specific wavelength ranges where CO absorbs strongly. This makes detection even more precise.

How Do They Reduce Interference?

Interference happens when a sensor reacts to other gases besides the target. Infrared filters solve this problem by isolating wavelengths beyond the precise wavelength associated with carbon monoxide absorption. This prevents confusion from gases like methane or water vapor.

This focus ensures readings stay accurate. It’s vital for critical tasks like safety monitoring or factory process control.

Can They Handle Tough Conditions?

Gas analyzers often work in harsh settings with extreme heat, humidity, or corrosive materials. Infrared filters are built tough. They are tested and refined with high-precision equipments. The product is used in fields like gas detection, instruments, and car industries.

Their strong design ensures they stay reliable, even in difficult conditions.

For experts looking for top-notch gas detection solutions, Bodian provides innovative infrared filter products for precise applications across many industries.

How Bodian’s Products Optimize CO Gas Detection Performance

Overview of Bodian’s Specialized Infrared Filters

Infrared filters are central to modern gas detection systems. They are the key part for accurately identifying and measuring carbon monoxide (CO) and other gases. As detection technology advances, the precision and reliability of these filters grow more important for industrial safety and environmental monitoring.

Key Features and Specifications of Bodian’s Infrared Filters

Infrared filters are crucial in gas detection, especially for CO analysis. They let specific wavelengths pass while blocking others. This enables precise detection of target gases. Our company offers infrared narrowband filters, infrared broadband filters, infrared long pass filters, infrared short pass filters, and infrared anti-reflection filters. Each type has a unique purpose, like improving sensitivity or reducing noise.

These filters are made with advanced materials and precise equipments. Infrared filters are sensitive components that use infrared optics. Their small “lenses” hold great power. Their sturdy build ensures they work well in tough industrial settings.

Compatibility with NDIR Sensor Technologies

NDIR sensors depend heavily on infrared filters. These sensors use an IR source and detector with a sample chamber in between. The filter’s job is critical. It isolates the light region where CO absorbs, ensuring only those wavelengths reach the detector.

Infrared filters use infrared optics principles. They are carefully designed and refined with advanced tools. This makes them work smoothly with NDIR systems, boosting accuracy and reliability.

Benefits of Using Bodian’s Solutions for Industrial Applications

Industrial settings often have challenges like high heat, humidity, or harsh chemicals. Infrared filters are built to handle these conditions without losing performance. Their durability makes them perfect for tasks like safety monitoring, process control, and environmental protection.

For professionals seeking advanced gas detection solutions, Bodian offers top-quality infrared filter products tailored for various industrial needs.

Practical Applications of Infrared Filters in Various Industries

Use Cases in Environmental Monitoring

Environmental monitoring systems use infrared filters to detect pollutants like CO with high accuracy. These systems benefit from the filters’ ability to pick specific wavelengths. This reduces interference from other gases or environmental factors. Detectors used in fields like environmental protection rely on this method.

Applications include air quality stations and portable analyzers for field tests. Their ability to give accurate readings at low gas levels makes them vital for regulations and public health.

Applications in Industrial Safety Systems

Industrial safety systems use gas analyzers with infrared filters to detect dangerous gases like CO. These systems prevent accidents from gas leaks or buildup in tight spaces.

By focusing on CO’s specific absorption bands, the filters ensure alarms go off only when needed. This reduces false alarms and ensures quick action during real emergencies.

Integration into Medical and Laboratory Equipment

Medical tools like respiratory monitors and lab instruments use infrared filters. These applications need high accuracy due to their critical nature.

In labs, spectrometers with these filters allow detailed gas analysis. Their flexibility with different wavelengths lets researchers customize experiments for specific needs.

Future Trends in CO Gas Detection Technology with Infrared Filters

Innovations in Filter Design for Better Precision

Advances in materials and coatings are leading to better infrared filter designs. Future versions aim to be even more precise. They will reduce reflection and increase light transmission at target wavelengths.

These improvements will make gas analyzers more reliable in all kinds of conditions.

Potential Advances in Smaller, Portable Devices

The push for smaller devices is driving compact gas detectors. Infrared filters are key to making smaller sensors that still perform well.

Portable analyzers with these tiny components will become more common for on-the-go environmental checks or factory inspections.

Growing Applications in New Markets

New markets offer chances to use CO detection with advanced infrared filters. Areas like smart cities, renewable energy, and self-driving cars will benefit greatly.

As concerns about air quality and safety grow, demand for these advanced solutions will rise quickly.

FAQs

Q1: What makes narrowband infrared filters good for CO detection?

A: Narrowband infrared filters focus on specific wavelengths where CO absorbs strongly. This greatly improves measurement accuracy.

Q2: Are there challenges with using infrared filters?

A: They are very effective, but challenges include staying strong in tough conditions. Advanced designs solve this through careful testing.

Q3: Can portable devices use miniaturized infrared filter technology?

A: Yes, smaller designs allow portable devices to stay high-performing. They are convenient for field tasks like environmental checks or factory inspections.