Infrared filters are super important for making thermal images clear and sharp. They help improve picture quality, cut down on noise, and make spotting targets easier in jobs like security or aerospace. Bodian’s cool IR filters—like narrowband, broadband, and anti-reflection types—offer custom solutions for MWIR and LWIR systems, keeping things clear and reliable in tough spots.

The Role of Infrared Filters in Thermal Imaging Systems

Infrared filters are key players in thermal imaging gear. Whether you’re using basic security cameras or high-end aerospace sensors, a good filter boosts image sharpness and target spotting. They’re not just sitting there—they shape the light your system sees to match what you need.

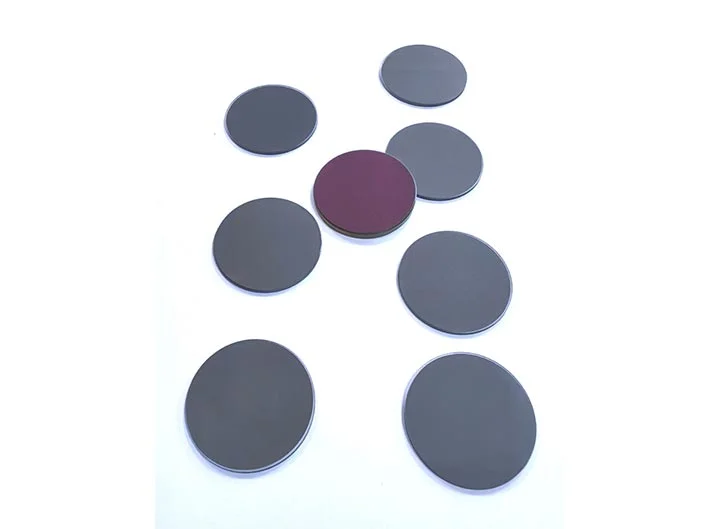

Infrared filters belong to infrared feature sensitive components, and their “small lenses” gather great wisdom. Infrared filters deeply apply the principles of infrared optics, undergo repeated research and precise design, and are refined through fully automated and high-precision advanced instruments.

The Function of Infrared Filters in Controlling Spectral Transmission

Thermal imaging systems work in specific light ranges, usually mid-wave infrared (MWIR: 3–5 µm) or long-wave infrared (LWIR: 8–14 µm). Infrared filters act like gatekeepers. They let only the right light waves hit the detector and block the rest. This cuts out extra light from things like sunlight and makes your system work better.

In recent years, our company has developed a new series of infrared filters: infrared narrowband filters, infrared broadband filters, infrared long pass filters, infrared short pass filters, and infrared anti-reflection filters. Each type is built for precise control over spectral transmission properties.

How Filters Improve Image Contrast, Clarity, and Signal-to-Noise Ratio

Clear thermal images need clean signals. Infrared filters boost the signal-to-noise ratio (SNR) by blocking out-of-band noise, like sunlight or heat from stuff you don’t care about. This gives you sharper pictures and better contrast—super handy in foggy weather or at night.

Importance of Filter Selection Based on Application Scenarios

The best filter depends on your job. Gas detection needs narrowband filters to catch specific light waves. Security cameras work better with broadband LWIR filters that grab a wide range of heat signals. The product is applied in various fields such as gas detection, infrared temperature measurement, infrared detection, infrared thermal imaging, instrumentation, automotive, healthcare, electronics, safety monitoring, aerospace, and national defense.

Key Parameters for Selecting Infrared Filters

Picking a filter isn’t just about light waves—it’s about matching specs to your needs.

Wavelength Range and Spectral Bandpass Characteristics

First, figure out your light range—MWIR or LWIR. Then, pick a filter with the right bandpass width. Narrowband filters are great for precise jobs like gas analysis. Broadband ones let in more light for general imaging.

In the visible and near ultraviolet regions, there is available a wide range of glass filters that solve most of the problems. In the infrared often the complete filter consists of several multilayers. This multilayer setup gives you tight control over edges and blocks unwanted light.

Optical Density and Transmission Efficiency

Optical density (OD) shows how well a filter stops unwanted light. High OD keeps out background noise, but you need good transmission in the passband to avoid losing your signal.

Environmental Durability and Coating Technologies

Tough environments need strong coatings. Anti-reflection coatings cut glare and stray light. Hard coatings resist scratches. Hydrophobic layers make cleaning easier. Your filter has to handle temperature changes without peeling or shifting.

Matching Filter Types to Infrared Detector Technologies

Your detector type decides what filter you need—matching them is a big deal.

Filters for MWIR Detectors

MWIR systems use cooled detectors. They’re great for spotting hot stuff like engines or leaks. These need narrowband or long-pass IR filters that fit their sensitivity range.

Filters for LWIR Detectors

LWIR systems work at room temperature with uncooled microbolometers. They need broader filters to catch more light since their signals are weaker. Broadband LWIR filters are perfect for grabbing heat from 8–14 µm while keeping noise low.

Compatibility with Uncooled vs. Cooled Detector Systems

Cooled detectors can use tighter filters because they’re more sensitive. Uncooled systems need more light due to lower sensitivity, so broadband or hybrid filters work better, balancing resolution and speed.

Application-Specific Filter Selection Strategies

Every job has its own challenges—your filter should handle them well.

Surveillance and Security Thermal Imaging

Security setups love broadband LWIR filters. They grab lots of heat signals across big areas, even in weird lighting. Anti-reflection coatings help cut flare from city lights.

Industrial Thermography and Process Monitoring

Industrial tools need filters that stay steady in changing temperatures. You want high transmission in ranges like 3–5 µm for furnace checks, plus coatings that fight dust and harsh gases.

Scientific Research and Aerospace Applications

Science and aerospace need top-notch filters with super clear optics. For space missions where weight matters, thin-film coated filters give precise light control and stay strong without adding bulk.

Integrating Bodian’s Infrared Filters into High-Performance Systems

Want to make your thermal imaging system super sharp? Bodian has a big lineup of filters for both standard and custom needs in MWIR and LWIR systems.

Their products include narrowband IR filters for gas sensing and broadband ones for security cameras. They use high-precision IAD tech to ensure every filter is spot-on across production runs.

Infrared filters are upstream components commonly used in gas analyzers, surveillance cameras, infrared sensors. With Bodian’s know-how in picking materials like germanium or silicon and building tough coatings for harsh or space environments, adding their filters to your system is a breeze.

Optimizing System Performance with Bodian Filter Solutions

A good filter doesn’t just make pictures clearer—it makes your whole job succeed by focusing on what matters.

Enhancing Target Detection in Complex Environments Using Bodian Filters

Tracking vehicles through smoke or spotting people in bushes? Bodian’s narrowband IR filters cut through background clutter by focusing on the right heat signals, not relying on fancy computer tricks.

Reducing Background Interference Through Selective Spectral Filtering

Using tricks like notch filtering around common air bands, you can cut false signals from warm surfaces or sunlight bouncing off metal.

Improving System Stability Under Harsh Environmental Conditions

Bodian’s tough coatings keep filters steady through quick temperature changes or shakes—super important for drones or satellites flying at different heights.

Practical Considerations for Implementation and Maintenance

Thermal optics need careful setup—not just for light but for mechanics—to stay aligned during use.

Mounting Techniques and Mechanical Integration with Optical Assemblies

Filters need stress-free mounts or bonded holders. These handle heat expansion without messing up light paths or causing tilt errors.

Cleaning, Handling, and Long-Term Reliability of IR Filters in Field Conditions

Field gear needs easy upkeep. Hydrophobic coatings make cleaning simple. Scratch-proof layers last longer. Sealed packaging stops moisture during storage—all stuff Bodian’s toolkit covers at Bodian Optics.

Summary of Best Practices in Selecting Infrared Filters for Thermal Imaging Systems

Picking an IR filter isn’t just about light waves—it’s about matching every detail to your gear and job:

- Check wavelength fit (MWIR/LWIR) for your detector.

- Balance blocking power with light flow.

- Pick coatings based on weather or dust exposure.

- Match filter precision to your task’s needs.

- Plan mounting during system design.

Need custom filters? Bodian’s support team can build ones that hit your optical and mechanical goals without cutting corners.

FAQ

Q1: What’s the difference between narrowband and broadband IR filters?

A: Narrowband IR filters let through a super specific range of wavelengths, great for gas detection where you need precision. Broadband IR filters allow wider ranges (like 8–14 µm), perfect for general thermal imaging to grab more signals.

Q2: How do I choose between MWIR vs LWIR compatible filters?

A: Go for MWIR filters if you use cooled detectors for hot targets like engines. Pick LWIR ones for uncooled microbolometers focused on human heat or outdoor security.

Q3: Can I clean my IR filter if it gets dirty during field use?

A: Yup—if it has protective coatings like hydrophobic layers. Use lint-free wipes with safe solvents and gentle pressure to avoid scratches. Always check Bodian’s care instructions.