The signal-to-noise ratio (SNR) decides how clear your measurements are in optical systems. Infrared filters boost SNR by picking out the right wavelengths and blocking noise. They make things super reliable for stuff like thermal imaging, gas sensing, and spectroscopy. Want to know how? Let’s dive in!

Signal-to-Noise Ratio and Its Importance

SNR Definition and Significance

In fancy optical systems, SNR shows how much good signal you get compared to pesky noise. A high SNR means the signal pops out clearly against the background. This leads to better measurements, sharper pictures, and stronger system performance. For things like infrared thermal imaging or gas detection, where tiny changes matter a lot, even a bit of SNR drop can mess things up big time.

Sources of Noise in Optical Measurements

Noise comes from all sorts of places. You’ve got heat changes in detectors, electronic buzz, stray light sneaking in, or even shaky vibrations. These things blur the real signal and make measurements less trustworthy. In infrared setups, background heat radiation is often the biggest troublemaker.

SNR’s Impact on Accuracy and Reliability

A low SNR can make images fuzzy, give wrong readings, or miss detections altogether. But a high SNR makes detection sharper and clearer. This is super important in fields like aerospace, medical testing, or eco-monitoring, where decisions depend on spot-on optical data.

Infrared Filters’ Role in Optical Systems

Spectral Filtering Mechanism of IR Filters

Infrared filters work by letting through only specific wavelengths and blocking the rest. This filtering grabs the signal you want and kicks out the noisy stuff. Infrared filters are sensitive parts, and their tiny lenses are packed with smarts. They use special coatings to bounce back or soak up unwanted light while letting the right bands pass through easily.

Types of Infrared Filters and Their Applications

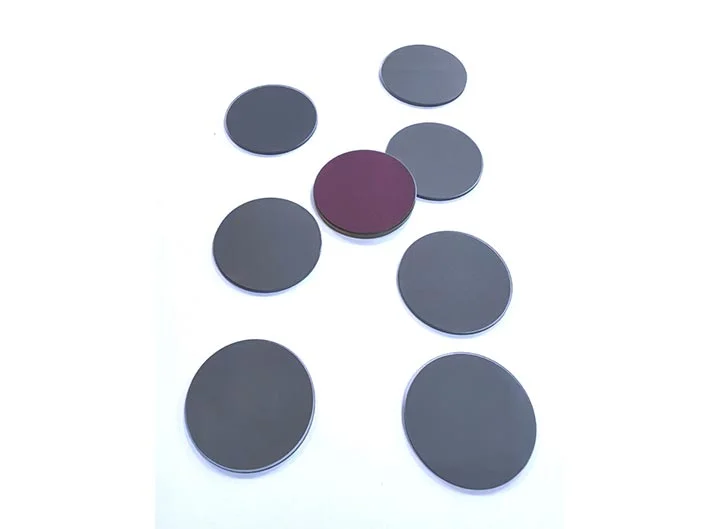

In recent years, our company has developed a new series of infrared filters: infrared narrowband filters, infrared broadband filters, infrared long pass filters, infrared short pass filters, and infrared anti reflection filters. Each has its own job. Narrowband filters zero in on exact wavelengths for gas analysis. Broadband ones let through wider ranges for thermal cameras. Long and short pass filters set clear wavelength edges. Anti-reflection coatings bump up light flow.

These filters show up in tons of places, like gas detection, infrared thermometers, thermal imaging, tools, cars, healthcare, electronics, safety checks, aerospace, and defense.

IR Filters’ Wavelength Selection and Background Noise Reduction

IR filters match their transmission bands to specific wavelengths, like CO₂ absorption lines or body heat emissions. This cuts out extra background radiation. It makes the signal stand out against the clutter, boosting clarity.

Ways Top-Notch Infrared Filters Boost SNR

Blocking Unwanted Background Light with Filters

Great IR filters stop stray radiation, like extra heat emissions, from flooding detectors with noise. Filters often use several layers to link the stop band’s edge to a solid absorption filter. This sharp cutoff keeps sensitive sensors safe from overload.

Spectral Isolation’s Enhancement of Detector Sensitivity

When only the right wavelengths hit your detector, thanks to tight filtering, the sensor works at its best. This cuts down baseline noise. As a result, even faint signals stand out clearly.

IR Filters’ Reduction of Crosstalk and Heat Noise

Crosstalk happens when wavelengths overlap and mess with each other. Narrowband IR filters with sharp edges and strong out-of-band blocking stop this. Plus, they cut out extra thermal IR from outside your target range. This lowers heat-related noise in the system.

Bodian Infrared Filters’ Use in Precision Tools

If you want awesome SNR for your optical system—whether for lab tools or industrial sensors—Bodian’s got you covered. Their advanced IR filters are built with precision and toughness in mind.

Bodian offers cool solutions like narrowband IR filters for gas sensing and broadband ones for wide-range thermal imaging. These are made with fully automated processes for consistent coatings. Infrared filters use infrared optics know-how, go through tons of testing, and are crafted with super precise tools. They work great in spectrometers or surveillance cameras, giving reliable results in tough settings, from labs to battlefields.

Considerations for Choosing Infrared Filters for High-SNR Systems

Importance of Matching Filter Bandpass to Target Wavelengths

To get the most SNR boost, your filter’s transmission band has to line up perfectly with your signal’s wavelength. For example, CO₂ detection needs filtering near 4.26 µm. Human skin temperature peaks around 9–10 µm. Each case needs custom tuning.

Materials and Coatings for Thermal Stability

The filter’s material affects how well it passes light and handles heat changes. Advanced coatings stay steady across big temperature swings without losing performance.

Importance of Toughness for Long-Term Use

Filters used outside or in rough industrial spots need to handle humidity, shocks, or UV damage. Strong coatings and sealed designs keep them working well, even after years of use.

System Performance With vs Without High-Quality Infrared Filters

Measurable SNR Improvements

Yup. Systems with top-notch IR filters can see up to 5 times better SNR by cutting background noise. They also lower dark current in cooled detectors and improve contrast at target wavelengths.

Real Examples of Improved Imaging with Filters

Night vision scopes get sharper images when stray IR is blocked well. Gas sensors have fewer false alarms when only the right wavelengths hit detectors. Medical thermography catches tiny temperature changes thanks to filtered signals.

Best Practices for Adding Bodian IR Filters to Your Design

When picking parts for your next optical system:

Figure out your wavelength range.

Pick narrowband or broadband filters based on your needs.

Check environmental needs: temperature range? Humidity resistance?

Look at product datasheets for transmission curves that match your sensor.

Think about custom filters if standard ones don’t fit.

Check out Bodian’s customizable infrared filter solutions for special needs in industries like aerospace or medical diagnostics.

FAQ

Q: Can I use regular glass filters for mid-infrared?

Nope. Glass filters work fine for visible or near-UV light, but infrared is trickier. You need multilayer designs instead of simple glass types.

Q: Are Bodian’s IR filters good for defense-grade gear?

Totally. They’re used in aerospace and defense because of their precision and toughness in extreme conditions.

Q: What’s the difference between shortwave-pass and longwave-pass IR filters?

Shortwave-pass filters let through shorter wavelengths and block longer ones. Longwave-pass filters do the opposite.