Infrared detection systems often struggle to isolate specific wavelengths amidst a flood of signals. For applications like gas sensing or thermal imaging, noise can overwhelm the data. Multi-layer IR filters address this challenge, offering precision and clarity.

At Bodian Optical Technology Co., Ltd., over four decades of expertise have gone into crafting these filters for real-world demands. This article explores their mechanics, benefits, and standout products from Bodian’s lineup, tailored for detector systems.

What Are Multi-Layer IR Filters

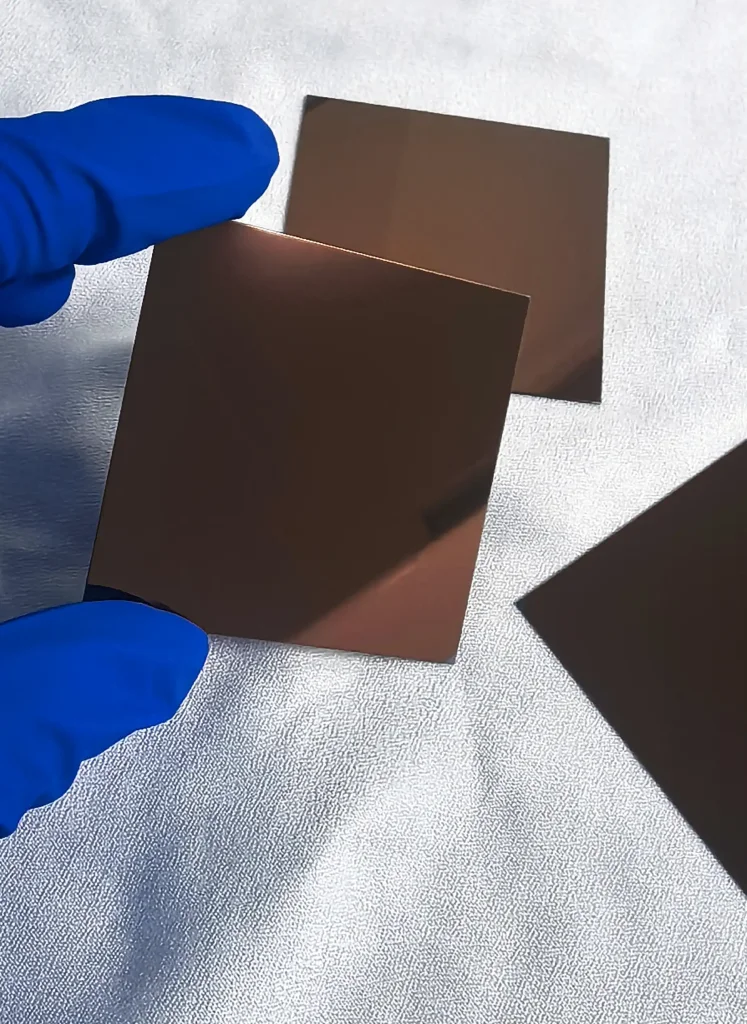

A thin substrate—germanium or silicon, perhaps a few millimeters wide—coated with dozens of dielectric films. That’s the essence of a multi-layer IR filter. Materials like zinc sulfide or calcium fluoride are layered onto these substrates to manipulate light with pinpoint accuracy.

Thin-Film Coatings on Substrates

These filters rely on nanometer-scale films, applied via vacuum deposition or magnetron sputtering. Germanium, favored for its ability to handle wavelengths up to 16 microns, dominates mid-IR applications. Silicon is another option, though less common. A recent project for a portable gas analyzer, used in dusty oil rigs, showcased germanium-based filters enduring 50 thermal cycles without deformation.

Designed for Infrared Wavelengths

Infrared spans 0.75 to 1000 microns, split into near, mid, and far regions. Filters target specific bands for detectors. For instance, Bodian’s ILP8200 long-pass filter allows wavelengths beyond 9 microns to pass while blocking shorter ones.

Enhance Detection Accuracy

Without filters, detectors capture unwanted signals, muddying results. Multi-layer designs use interference to sharpen passbands, delivering cleaner data. In a lab test last year, integrating a multi-layer filter into a CO2 monitor improved signal clarity by 25%, eliminating false positives from stray sunlight.

How Do Multi-Layer Designs Boost Selectivity

The magic lies in the stack. Each layer shifts the transmitance of incoming light, transforming chaos into precision. It’s like tuning an instrument to hit the exact note needed for a clear signal.

Layered Interference Effects

Light reflects and refracts through each film, with constructive interference amplifying the target wavelength and destructive interference suppressing others. Designs with 50+ layers achieve steep transition edges. A spectroscopy client reported crosstalk dropping from 5% to under 0.5% with Bodian’s narrowband filters.

Precise Wavelength Isolation

Filters lock onto specific wavelengths, like the 10.485-micron center of Bodian’s INBP10485, with a bandwidth around 1% of that value. This precision ensures detectors ignore irrelevant signals. In a wastewater plant’s methane monitoring system, such isolation prevented erratic alerts despite high humidity.

Reduced Noise Interference

Out-of-band light is blocked with optical densities (OD) exceeding 4, meaning transmittance drops below 0.01% outside the passband. This cuts background noise significantly. In IR arrays, this can mean the difference between reliable data and hours of debugging in tough conditions.

What Advantages Do They Provide in Detectors

High-performance detectors demand efficiency without added complexity. Multi-layer filters deliver that edge, enhancing performance while keeping systems streamlined.

High Transmittance Peaks

Expect 90% or better transmittance in the passband. The INBP10485 hits ≥90% at its peak, reducing signal loss and extending battery life in portable devices. A medical imaging client noted a two-hour runtime boost in their handheld unit thanks to this efficiency.

Deep Cut-Off Depths

Blocking is robust, with T < 1% across wide ranges like 100-16,000 nm (OD3). This ensures crisp thermal images without visible light interference. In night-vision systems, this clarity is critical for spotting targets in low-visibility settings.

Improved Signal-to-Noise Ratios

Signal-to-noise ratio (SNR) gains of 10-20 dB are common with proper filtering. By minimizing stray light, these filters boost detector sensitivity. In gas detection, a 15 dB SNR increase turned marginal trace CO readings into reliable detections.

Which Industries Benefit from These Filters

From labs to industrial sites, multi-layer IR filters serve wherever infrared signals matter. Bodian Optical customizes them for harsh environments, offering tailored sizes and anti-reflective coatings.

Gas Detection Systems

For CO2, methane, or NO2 monitoring, narrowband filters like INBP12285 (12.285 microns, 80% T) excel. In pipeline inspections or HVAC checks, one setup using this filter detected a 2% gas leak in under a minute, earning praise from safety teams.

Thermal Imaging Applications

Thermal cameras and fever scanners rely on long-pass filters like ILP8200 (80% T from 9-14 microns) to block visible light and highlight heat signatures. Drones equipped with these filters perform reliably in fog, as seen in border patrol operations.

Environmental Monitoring Tools

Air and water quality sensors use filters to isolate pollutant-specific bands. Urban deployments with Bodian filters handled -20°C temperature swings without spectral drift. Plus, RoHS compliance keeps them eco-friendly.

How Does Bodian Optical Excel in IR Filters

Since 1978, Bodian Optical has refined its craft, moving from trial-and-error to precision with German Leybold and Japanese Optorun equipment. It’s not just the tools—it’s the team perfecting the process for specific needs.

Advanced Coating Technology

Magnetron sputtering ensures dense, uniform films; e-beam evaporation delivers purity. Uniformity stays within 1% across a 12-inch wafer, verified by PerkinElmer spectrometers from near-IR to far-IR. The sputter machines hum like vintage appliances, but the results are cutting-edge.

Customizable Product Options

Need a 25mm round filter with steep edges? No problem. Sizes range from 5mm to 200mm, in squares or custom shapes, with optional AR coatings. Aerospace clients have tested these filters to withstand 10g shocks, proving their durability.

Reliable Performance Metrics

Expect ≥90% T, OD>3, and stability up to 200°C. ISO 9001 certification backs every batch. A six-month trial in Saudi Arabia’s heat showed zero degradation, setting Bodian apart for reliability in extreme conditions.

What Specific Bodian Products Are Recommended

Three standout products from Bodian’s IR lineup are ready to enhance detector performance, each addressing common application challenges.

INBP10485 for Narrowband Needs

Centered at 10.485 microns with a 1035 nm bandwidth and 90% peak T, this filter blocks 100-16,000 nm effectively. It’s a favorite for CO2 and ozone detection in biochem labs, reducing noise by 30% in prototype tests. Stock units start at $150, pairing well with InGaAs arrays.

INBP12285 for Broadband Coverage

This narrowband filter, with a 12.285-micron CWL and 900 nm HPB at 80% T, blocks 400-15,000 nm. It suits multi-gas analyzers and astronomical detectors, enabling environmental crews to track hydrocarbons and SO2. A drone-mounted unit achieved 50m standoff readings.

ILP8200 for Long-Pass Filtering

With a 7.1-micron cut-on and 80% T up to 14 microns, this filter blocks 1.5-7.1 microns (T≤1%). It’s ideal for human detection and industrial thermals, enhancing security camera clarity. A fever scanner trial showed 15% sharper forehead readings, even in high humidity.

Why Integrate These into Detector Systems

Adding a multi-layer IR filter transforms detector performance, blending seamlessly into existing setups with measurable gains.

Cost-Effective Performance Gains

The price of inventory filters ranges from $100 to $300, and customized products need to be evaluated based on specific product specifications. The payoff? Fewer false alarms and longer uptime. A factory client recovered costs in three months through improved yields, proving the value of precision filtering.

Proven Industry Applications

From oil fields to operating rooms, these filters perform excellently.

Multi-layer IR filters are more than components—they’re the key to sharper, cleaner signals in infrared detection. Bodian Optical’s 40+ years of expertise, backed by advanced equipment and rigorous testing, ensure products that meet the toughest demands.

FAQ

Q1: How to choose the right Bodian IR filter for a gas detector?

A: Match the filter to the target gas—CO2 pairs well with INBP4260. Narrow bandwidths suit trace detection; wider ones handle multi-gas. Share sensor specs for a tailored recommendation.

Q2: Can these filters withstand outdoor conditions?

A: Absolutely. Most endure -50°C to 200°C and high humidity. Germanium substrates resist shocks, but extreme setups may need hermetic seals. Desert trials showed no drift after months.

Q3: What’s the lead time for custom IR filters?

A: Stock ships in a week. Custom orders take 4-6 weeks, depending on layer complexity. Rush prototypes? Delivered in 10 days with early curve specs.