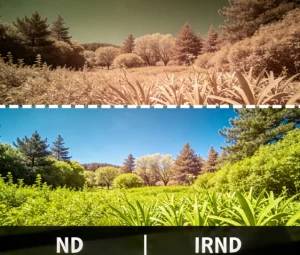

Optical systems today rarely work within a single, clean wavelength range. Cameras, sensors, and analytical instruments are often exposed to visible light, near-infrared, and long-wave infrared at the same time. This overlap makes filter selection more complex than it used to be. Among the most discussed options are ND filters and IRND filters, both designed to manage light intensity, but with very different behaviors once infrared enters the picture.

Understanding where ND filters stop being effective, and how IRND and infrared long wave pass filters step in, is essential for stable system performance. For manufacturers and integrators working in infrared detection, imaging, and spectroscopy, this difference is not theoretical. It directly affects accuracy, signal stability, and long-term reliability.

What Are ND and IRND Filters Used For in Optical Systems?

Before comparing performance limits, it helps to look at how ND and IRND filters are typically applied in real optical setups. Although they sound similar, their roles inside a system are not interchangeable.

Neutral Density Light Attenuation Across Broad Spectra

ND filters, or neutral density filters, are designed to reduce light intensity without changing the spectral shape too much. In practical terms, they lower brightness while keeping color balance relatively stable within the visible range. This makes them common in machine vision cameras, laboratory imaging, and laser power control where sensors can be easily saturated.

Between roughly 400 and 700 nm, high-quality ND filters perform as expected. Outside this range, especially beyond 750 nm, their attenuation becomes far less predictable. Many standard ND coatings simply were not designed with infrared in mind.

| Parameter | Typical ND Filter |

| Primary working range | 400–700 nm |

| Attenuation behavior | Uniform in visible light |

| Infrared control | Limited or uncontrolled |

| Common materials | Absorptive glass or metal films |

This limitation often goes unnoticed until infrared-sensitive detectors are introduced into the system.

Between ND and IRND solutions, the first separation point appears when infrared energy begins to affect sensor output.

Infrared Leakage Control in Mixed-Spectrum Environments

IRND filters were developed to address this exact gap. While they still attenuate visible light, they also introduce blocking or suppression in the infrared region. This helps prevent unwanted IR energy from reaching the detector, which is especially important for CCD, CMOS, and InGaAs sensors that respond well beyond visible wavelengths.

Unlike standard ND filters, IRND filters are engineered with combined absorptive and interference structures. This allows more consistent behavior across a wider spectrum.

| Parameter | IRND Filter |

| Visible attenuation | Controlled |

| Infrared blocking | Strong, defined |

| Typical cutoff | Mid-wave infrared to long-wave infrared band depending on design |

| Use cases | Vision systems, mixed-light environments |

Still, IRND filters are not a full solution for applications that intentionally rely on infrared signals.

Application-Driven Selection Criteria

Once systems move from “blocking infrared” to “using infrared,” both ND and IRND filters start to fall short. Infrared detection, thermal analysis, and gas sensing require selective transmission rather than simple attenuation. This is where long wave pass filters enter the picture, acting not as light reducers, but as wavelength gatekeepers.

Why Do Standard ND Filters Fail in Infrared Applications?

In infrared systems, filter performance is judged less by brightness control and more by spectral precision. ND filters struggle in this environment for structural reasons.

Non-Uniform Attenuation Beyond the Visible Range

Most ND filters rely on absorptive glass or thin metallic coatings. These materials behave differently once wavelengths move into near- and mid-infrared regions. Absorption drops, reflections increase, and the attenuation curve becomes uneven.

This leads to unstable signal levels, especially when environmental temperature or light conditions change. In imaging systems, this often appears as drifting contrast or inconsistent grayscale output.

Transitioning from attenuation problems, detector behavior further amplifies the issue.

Sensor Sensitivity to Long-Wave Infrared Signals

Modern infrared sensors are designed to capture weak signals. When unintended infrared light leaks through an ND filter, the detector does exactly what it was designed to do: respond strongly. The result is noise, signal offset, or false readings.

This is common in systems combining visible alignment optics with infrared measurement channels. Even small leakage above 800 nm can distort results.

As systems become more infrared-focused, blocking alone no longer solves the problem.

Need for Dedicated Infrared Spectral Control

Infrared applications demand filters with sharp transitions, high transmission in the passband, and deep rejection elsewhere. This is beyond what ND or IRND filters were meant to handle. Long wave pass filters, designed through multilayer thin-film interference, provide that level of control.

How Do Infrared Long Wave Pass Filters Complement IRND Designs?

Infrared long wave pass filters do not compete with IRND filters. Instead, they complete the spectral management chain where infrared signals are the target rather than the threat.

Defined Cut-On Wavelength for Infrared Isolation

An infrared long wave pass filter transmits wavelengths longer than a defined cut-on point while blocking shorter wavelengths. This allows precise separation between visible, near-infrared, and mid-infrared regions.

| Filter Type | Cut-On Wavelength | Transmission Region |

| ILP5500 | ~5.5 µm | Mid-infrared |

| ILP8200 | ~8.2 µm | Thermal IR |

| ILP10000 | ~10 µm | Long-wave IR |

This clarity is essential for thermal imaging, gas detection, and infrared spectroscopy. With wavelength control established, transmission quality becomes the next priority.

High Transmittance in Target Infrared Bands

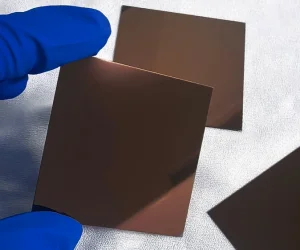

Bodian Optical’s ILP series is engineered for high transmittance in the working infrared band while maintaining deep blocking below the cut-on wavelength. Typical transmission exceeds 90% within the passband, a requirement for low-signal infrared systems.

Such performance is achieved through decades of coating experience and precision thickness control, rather than trial-and-error designs.

Performance alone is not enough if stability cannot be maintained.

Stable Performance Under Industrial Conditions

Infrared systems often operate in environments with temperature swings, vibration, and long duty cycles. The ILP filters are produced using advanced magnetron sputtering and vacuum evaporation equipment, delivering dense, stable film structures that resist spectral drift over time.

This reliability makes them suitable for medical devices, aerospace optics, and industrial monitoring systems.

Which Bodian Optical ILP Filters Support Advanced Infrared Applications?

With a full ILP portfolio, Bodian Optical offers wavelength-specific solutions rather than one-size-fits-all products.

ILP5500 for Near- to Mid-Infrared Transition Control

The ILP5500 Infrared Long Wave Pass Filter is designed for systems working around the boundary between near- and mid-infrared. It is commonly used in analytical instruments and controlled heating measurements where shorter wavelengths must be rejected.

ILP8200 for Mid-Infrared Detection and Imaging

The ILP8200 targets thermal infrared applications, including infrared imaging and gas analysis. Its sharp cut-on and high passband transmission make it suitable for detectors operating in the 8–12 µm range.

ILP10000 for Long-Wave Infrared Precision Systems

For long-wave infrared systems, the ILP10000 provides reliable transmission beyond 10 µm. It is widely used in defense, aerospace, and high-end scientific research where spectral accuracy cannot be compromised.

How to Choose Between ND, IRND, and ILP Filters for Your System?

Selecting the right filter is less about category names and more about understanding the system’s spectral priorities.

Optical System Spectral Range Assessment

If the system operates mainly in visible light, ND or IRND filters may be sufficient. Once infrared signals become part of the measurement, long wave pass filters are no longer optional.

Detector Type and Signal-to-Noise Requirements

Infrared detectors amplify small signals. Filters that leak or distort infrared energy directly reduce signal-to-noise performance. ILP filters provide controlled transmission where it matters.

Customization and Coating Expertise Considerations

Bodian Optical supports custom wavelengths, substrates, and dimensions across ultraviolet, visible, and infrared ranges. This flexibility allows filters to be matched precisely to system optics, rather than forcing system changes around standard parts.

FAQ

Q1: Can an IRND filter replace an infrared long wave pass filter?

A: No. IRND filters are designed to suppress infrared, while long wave pass filters are designed to transmit specific infrared bands. Their functions are fundamentally different.

Q2: Are ILP filters suitable for high-temperature environments?

A: Yes. The dense thin-film coatings used by Bodian Optical provide strong thermal stability, making ILP filters suitable for industrial and scientific applications.

Q3: Is customization available for non-standard wavelengths?

A: Yes. Bodian Optical offers wavelength, size, and substrate customization based on system requirements, supported by in-house coating and testing capabilities.