Across environmental monitoring, industrial process control, medical safety, and even the storage of fresh food, the demand for real-time, precise analysis of multiple gases keeps rising. Traditional approaches often rely on bulky setups or separate modules for each gas, which slows response time and creates new sources of error. Modern non-dispersive infrared (NDIR) technology has changed that picture. Today, advanced platforms—such as the multi-gas NDIR modules used widely in global sensing markets—can read CO₂, NO, SO₂, N₂O, refrigerants, ethylene, and other gases in parallel, all within one compact optical path.

Behind that impressive leap sits a component that rarely gets public attention: the infrared optical filter. Small in appearance, but decisive in function, the filter acts like a gatekeeper that sorts light with the precision of a “spectral fingerprint scanner.” Its job is deceptively simple—allow only the right wavelengths to pass—but the quality of this step determines whether the entire sensor can reach laboratory-grade stability while surviving real-world environments.

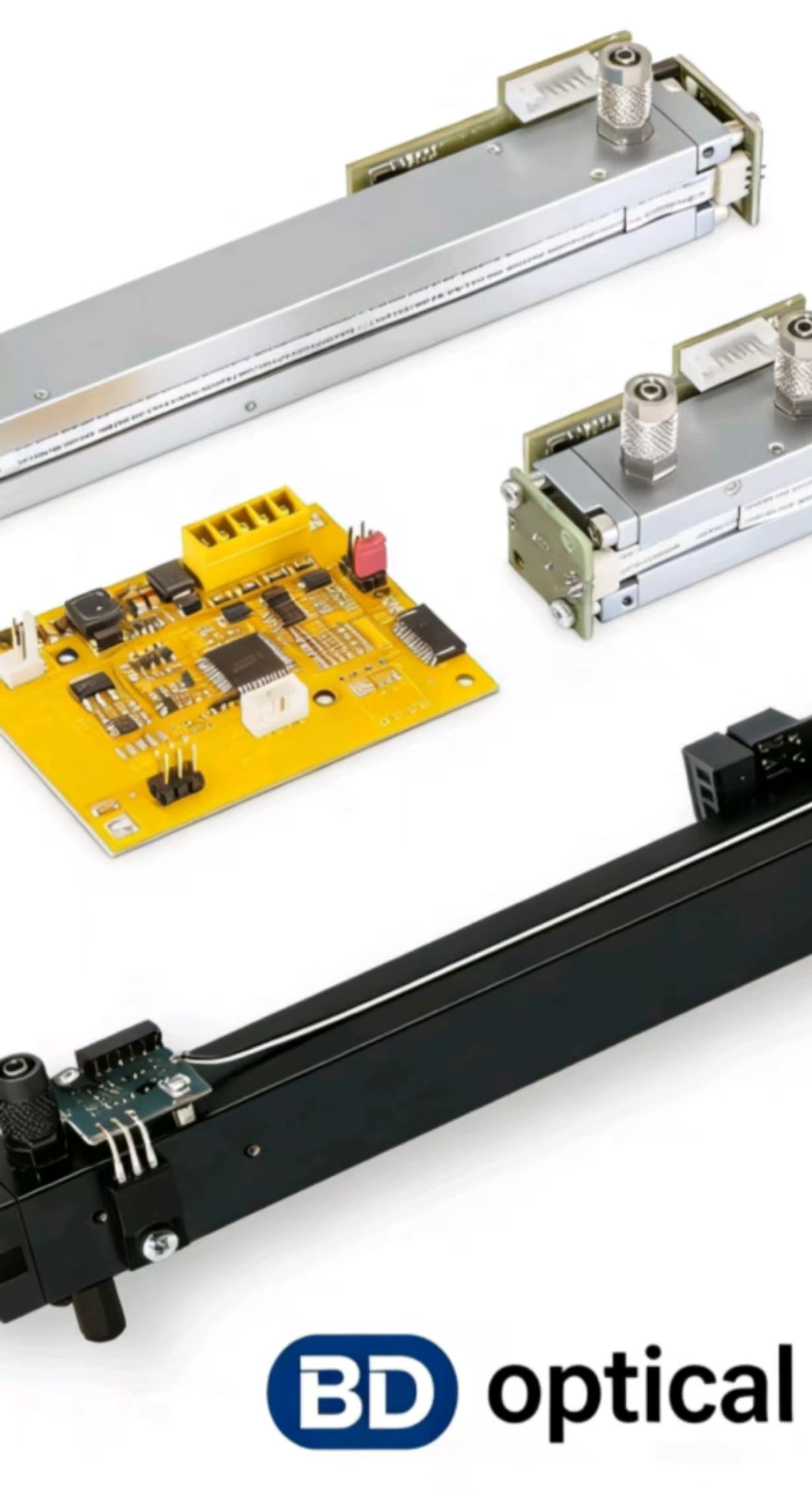

For companies such as Bodian Optical, a manufacturer with more than 40 years of experience in optical thin-film engineering, the performance of these filters is both a science and a craft. Their infrared narrowband, broadband, long-pass, short-pass, and anti-reflection filters support demanding uses in gas analysis, infrared imaging, temperature sensing, medical diagnostics, aerospace, and defense. Understanding how filters function inside NDIR systems helps explain why thin-film design and long-term stability matter so much today.

Unpacking the Core Challenge: Extracting “Clean” Signals from a Mixed Infrared Spectrum

NDIR works on a straightforward physical principle: every gas selectively absorbs infrared energy at certain wavelengths. These absorption lines form a unique “fingerprint.” When infrared light travels through a gas chamber, the drop in intensity at those specific wavelengths reveals the gas concentration.

The real difficulty is that the detector doesn’t receive a neat, isolated line. Instead, it receives a dense, overlapping mix of spectral information—multiple gases, humidity, stray light, and environmental noise all packed together. Measuring this combined intensity alone won’t tell any sensor which gas absorbed what.

This is where infrared filters step in. A well-designed narrowband filter sharply isolates only the tiny band around a target gas’s absorption peak—4.26 μm for CO₂, around 5.3 μm for NO, or roughly 7.3 μm for SO₂. Everything else is blocked, often to optical densities of OD3 or deeper. The filter essentially performs optical purification, carving out clean measurement channels that allow the detector to assign changes in intensity to the correct gas with confidence.

This physical separation of light is the foundation of multi-gas NDIR. Without filters, mathematical compensation would never fully resolve the spectral mix.

How Infrared Filters Enable High-Performance Multi-Gas NDIR Systems

In multi-gas modules, one infrared source illuminates a chamber shared by all sensing channels. On the detection side, carefully designed filter sets guide the correct wavelengths toward individual detectors. This structure allows different gases to be measured simultaneously, not sequentially.

Below are three roles in which the filter becomes indispensable.

1. Building Independent Optical Channels Inside One Sensor

Each gas channel requires a filter whose center wavelength, bandwidth, and blocking curve match its absorption signature. Even slight deviations in center wavelength can distort readings at low concentration levels. Because the channels all use the same light source, stability from channel to channel is essential for parallel measurement.

Manufacturers like Bodian achieve this through thin-film stacks deposited via vacuum evaporation, magnetron sputtering, or ion-assisted coating, using materials such as germanium, silicon, sapphire, and others. With advanced equipment—Leybold, Optorun, and imported spectroscopic testing equipment—the company can maintain tight tolerances across UV, visible, and infrared bands, ensuring filters from the same batch match in spectral behavior.

The result is a multi-channel design where CO₂, NO, SO₂ or refrigerants can be measured at the same moment with minimal drift.

2. Reducing Cross-Sensitivity Through Deep Blocking and Precise Band Edges

Overlapping absorption lines create cross-talk, a notorious challenge in NDIR. Water vapor or methane, for example, can interfere with CO₂ readings. A high-quality narrowband filter minimizes such issues by combining:

- High transmittance in-band(often >90%)

- Extremely low out-of-band leakage

- Sharp slopes at both edges of the passband

These traits are achieved through multi-layer film designs based on quarter-wave stacks, symmetric multilayers, and ripple-suppression structures extensively studied in thin-film theory. Filters with deeper blocking levels and better matching to detector and substrate admittance naturally offer lower cross-sensitivity. That stability is key for long-term monitoring in environments where temperature and humidity fluctuate sharply.

3. Sustaining Calibration Stability Under Temperature and Pressure Change

A multi-gas sensor must operate reliably for years. That means the filter must maintain:

- Center wavelength stabilityunder thermal expansion

- Low driftfrom humidity or mechanical stress

- Durabilityacross −50°C to 200°C, depending on the application

Long-term reliability depends heavily on thin-film microstructure, deposition uniformity, and substrate choice—all topics deeply embedded in Bodian’s R&D work. Their strict process control, cleaning standards, and environmental testing help reduce wavelength shifts that would otherwise accumulate into calibration error.

Stable optical channels also help algorithms perform more accurate pressure compensation, a critical step for gases with pressure-dependent absorption.

Application Reach: How Custom Filters Expand the Boundaries of NDIR Sensing

Infrared filter design is flexible. By tailoring center wavelength, bandwidth, size, and substrate, engineers can extend NDIR into industries that once required much more complex analytical tools.

Here are key examples:

Refrigerant Leak Monitoring

Different refrigerants—R134a, R410A, R32, and others—carry strong IR fingerprints. Custom filters tuned to these ranges allow leak detectors to identify and quantify trace vapor for HVAC maintenance and industrial safety.

N₂O Monitoring in Medicine and Climate Research

N₂O’s strong absorption bands near 4.5 μm and 7.8 μm require stable, low-drift filters to avoid noise during anesthesia monitoring or greenhouse gas research.

Food Preservation and Controlled-Atmosphere Storage

Ethylene promotes fruit ripening; CO₂ slows respiration. Filters tuned to ~10.6 μm for ethylene and 4.26 μm for CO₂ allow one sensor to coordinate ventilation and chemical control in warehouses, extending shelf life and reducing waste.

Safety, Aerospace, and Industrial Sensing

Because IR filters withstand wide temperature swings, vibration, and harsh air chemistry, they support use in combustion analysis, satellite payloads, and military optics.

Across these cases, custom filter engineering is what allows one optical platform to serve multiple markets without redesigning the entire sensor.

Why Companies Turn to Bodian for High-End Infrared Filters

With its roots tracing back to the Beijing Film Machinery Research Institute established in 1978, Bodian has built decades of expertise across coating design, deposition science, and material study. A few competitive strengths often highlighted by customers include:

- High-precision thin-film designwith ultra-narrow bandwidths, high transmission, and OD6+ blocking

- Rapid customizationof wavelength, size, and film structure for small batches or new gas species

- Fully integrated production, from substrate machining to coating and full-spectrum testing

- Strict quality managementwith ISO-based systems and automated measurement tools

- Strong cost-performance ratio, supporting domestic substitution in high-end optics

Their IR filter lines—INBP, IWBP, ILP, ISP, IAR—cover most needs in NDIR, infrared imaging, thermometry, and defense-grade sensing, helping customers build reliable products more quickly.

Conclusion: A Small Filter That Unlocks Big Possibilities

In a modern NDIR sensor, the infrared source may act as the “speaker,” the gas mixture may serve as the “sheet music,” and the detector may be the “listener.” But the infrared filter is the conductor. It decides which wavelengths reach the detector, which signals stay out, and how clearly each gas’s fingerprint is expressed.

When filters are stable, deeply blocking, and precisely tuned, the entire system gains clarity—multi-gas sensing becomes faster, cleaner, and more reliable. As industries look for compact, intelligent monitoring tools, infrared filters remain one of the quiet technologies powering that transformation.

FAQs

Q1: Why is narrowband filtering so critical for multi-gas NDIR sensors?

A: Because several gases absorb in nearby regions, a narrowband filter isolates only the desired spectral line. This reduces cross-talk and allows one detector to respond to one gas channel with minimal interference.

Q2: What materials are commonly used for infrared filters?

A: Depending on wavelength, substrates often include germanium, silicon, zinc sulfide, zinc selenide, and calcium fluoride. Thin-film stacks use dielectric or metal layers selected for their refractive index contrast and stability.

Q3: Can infrared filters be customized for new or emerging gases?

A: Yes. By adjusting center wavelength, bandwidth, and substrate, manufacturers like Bodian can rapidly develop filters for refrigerants, hydrocarbons, anesthetic gases, or specialty industrial emissions.