Thermographic imaging has become one of the most dependable tools in modern aerospace engineering. Aircraft manufacturers and space agencies rely on thermal cameras to assess engine health, monitor heat signatures across fuselages, and capture environmental data from high-altitude platforms. As imaging systems evolve, the quality of infrared filtering used in these instruments plays a decisive role. The global thermal imaging market, critical for aerospace applications, was valued at USD 4.63 billion in 2023 and is projected to reach USD 7.59 billion by 2030, growing at a CAGR of 7.3%, with the aerospace and defense segment accounting for 21.2% of the market share in 2023.

Aerospace conditions—rapid temperature swings, intense vibration, and wide spectral demands—push optical components to their limits. This is why long wave pass filters (LWPFs) from companies such as Bodian Optical have become essential parts inside advanced thermographic systems.

Why Do Aerospace Thermographic Systems Require More Accurate Infrared Filtering?

As thermal cameras extend their role in both manned and unmanned aerospace platforms, their filtering performance becomes a critical factor. The gap between what sensors can detect and what the atmosphere allows through is often wide, so filters help shape a cleaner, more usable signal.

Thermal Noise Suppression

Before moving deeper into imaging applications, it helps to consider that aircraft surfaces and internal components emit a large amount of infrared radiation. Without proper filtering, the detector receives a flood of stray thermal noise. Long wave pass filters help suppress unwanted wavelengths below the cut-on point, limiting sensor overload and leading to cleaner imagery. This is particularly important for aerospace engines, where temperature gradients often exceed 800°C during operation, making it difficult to isolate useful signatures.

Enhanced Signal-To-Background Separation

Airborne cameras deal with complex backgrounds—sky glare, ground heat reflection, and atmospheric moisture. A precise LWPF helps separate genuine heat events from irrelevant background emissions. This difference becomes even more valuable in satellite systems orbiting at altitudes where atmospheric scattering causes measurable shifts in incoming IR signals.

Improved Detection in Long-Distance Scenarios

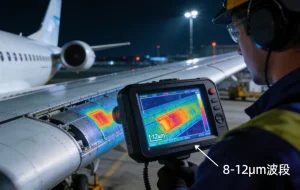

Long-range detection demands filters with high transmission rates in specific wavebands. Atmospheric windows at 3–5 μm and 8–12 μm are widely used for aerospace imaging. A well-designed filter reduces signal loss in these windows, allowing detectors to pick up subtle thermal differences from great distances. Even a 3–5% improvement in transmission can significantly sharpen the temperature reading during structural inspections or early anomaly detection.

How Do Long Wave Pass Filters Support High-Resolution Thermal Imaging?

Aerospace thermal imaging systems rely heavily on consistent and repeatable optical performance. The way long wave pass filters handle spectral separation directly affects image clarity. This is where thin-film design becomes central.

Selective Wavelength Transmission

Long wave pass filters let only longer wavelengths through while blocking shorter bands. For thermographic imaging, this controlled transmission reduces interference from non-target wavelengths. For example, Bodian Optical’s LWPF series uses multilayer thin-film structures to maintain stable transmission curves, which is particularly helpful when detecting micro-cracks or hot spots on aircraft wings.

Stable Performance Across Harsh Temperature Conditions

Aerospace applications introduce temperature swings that range from -55°C at cruising altitudes to over 100°C around certain aircraft components. Filters therefore need durable thin-film structures and stable materials. High-stability IR coatings help prevent spectral drift, meaning imaging systems remain accurate even during long missions or repeated heating cycles.

Optimized Imaging Through Reduced Optical Losses

Reducing the number of reflections inside the filter stack improves overall sensitivity. Although different manufacturers use varying methods, Bodian Optical applies high-uniformity coating processes that lower reflection loss while keeping film surfaces smooth. The effect is cleaner signals during high-resolution thermal inspections, especially where tiny hot spots—sometimes only a few degrees above ambient—need to be captured.

Where Can Specialized Infrared Filters Enhance Aerospace Monitoring Tasks?

Aerospace thermal imaging goes far beyond basic temperature checks. As aircraft become more complex and safety requirements tighten, IR cameras equipped with high-quality filters serve multiple functions.

Aircraft Structural Health Inspection

Thermal cameras use the 8–12 μm band to detect delamination, insulation loss, and surface fatigue. Since these defects often show only slight thermal variations, a clean spectral response is vital. Filters that effectively isolate long-wave radiation help technicians spot problems early, reducing maintenance cost and downtime.

Satellite-Based Environmental Observation

Earth-observing satellites rely on long-wave IR bands to monitor land surface temperature, volcanic activity, cloud formation, and sea surface changes. A filter with stable cut-on wavelengths helps reduce atmospheric distortion and increases accuracy in thermal gradient measurements. Some satellites require transmission stability within ±1% across a large temperature range, which is where precise thin-film filters prove valuable. The ESA Copernicus Land Surface Temperature Monitoring (LSTM) mission, set for launch in the late 2020s, will use thermal infrared sensors to provide high-resolution land surface temperature data with ±1% stability, supporting volcanic activity and sea surface monitoring with reduced atmospheric distortion.

Engine Testing and Thermal Diagnostics

During engine development, capturing detailed thermal maps helps engineers validate combustion efficiency and airflow. With high-temperature zones reaching up to 1,500°C, only long-wave infrared components with high resistance to thermal stress can maintain performance. LWPFs that maintain consistent transmission curves under such heat support reliable data output.

What Makes Bodian Optical’s Filters Suitable for Advanced Aerospace Applications?

Bodian Optical has built its product line around stable, repeatable thin-film design. With more than 40 years of coating research, its product series is widely used in thermal imaging, aerospace sensing, and scientific instrument development.

High Uniformity Thin-Film Construction

The company operates advanced coating systems such as Leybold and Optorun platforms, offering consistent film thickness and superior surface quality. This uniformity translates directly to reduced wavefront distortion and stable long-wave transmission—two factors crucial in aerospace optics.

Customizable Wavelength Cut-On Options

Aerospace missions often require wavelength tuning. Bodian’s LWPF series can be manufactured with different cut-on points, letting integrators match filters with specific thermal sensors. The ILP10600, ILP3000, and ILP7700 each serve different detection bands, making them suitable across thermal cameras, satellite payloads, and airborne inspection units.

Reliable Coating Stability for Extreme Environments

Bodian’s coating materials are chosen for robustness in harsh conditions, including vibration, rapid thermal swings, and long-term radiation exposure. This durability helps maintain stable performance throughout the life cycle of aircraft systems or space instruments, reducing the risk of spectral drift.

How Do Different LWPF Models Meet Varied Aerospace Imaging Needs?

Before selecting an infrared filter, aerospace engineers compare wavelength range, transmittance, and physical robustness. Bodian Optical offers three long wave pass filters suited for different roles in airborne and space-based imaging.

ILP10600 for Ultra-Long Wavelength Detection

This filter is designed for the 10.6 μm region, commonly used in advanced airborne detection instruments and environmental sensing modules. Its strong long-wave transmission makes it suitable for high-altitude inspections, especially where atmospheric interference is minimal.

ILP3000 for Broad-System Compatibility

Operating around the 3 μm band, this model covers applications in both mid-wave and long-wave thermal systems. Aircraft engine diagnostic tools and certain satellite sensors often use this range to detect fuel combustion patterns and engine temperature variations.

ILP7700 for High-Sensitivity Mid-to-Long Wave Systems

The 7.7 μm region offers a balance between atmospheric transparency and detector sensitivity. This filter is typically integrated into thermal cameras used for structural monitoring, aircraft safety inspections, and onboard surveillance tasks. Its stable cut-on behavior makes it reliable during rapid temperature changes.

Real Industry Data: Infrared Bands Used in Aerospace Thermography

A quick look at widely adopted wavebands shows why the above filters align with modern aerospace needs.

| Aerospace Application | Common IR Band | Reason for Use |

| Aircraft Wing Thermal Inspection | 8–12 μm | High contrast for structural defects |

| Satellite Surface Temperature Mapping | 10–12 μm | Reduced atmospheric noise |

| Engine Combustion Diagnostics | 3–5 μm | Strong emission during combustion |

| Atmospheric Window for Long-Distance Detection | 7–8 μm | Good penetration through moisture |

These values come directly from standard infrared imaging references across aerospace programs and thermal testing laboratories.

FAQs

Q1: What makes a long wave pass filter useful for aircraft inspections?

A: It blocks shorter wavelengths and passes longer ones in the thermal band, helping cameras read temperature differences more clearly during structural checks.

Q2: Are infrared filters affected by large temperature swings during flight?

A: High-quality thin-film filters—such as those from Bodian Optical—are designed to stay stable across wide temperature changes, keeping the transmission curve consistent.

Q3: Do different aerospace sensors need different LWPF cut-on wavelengths?

A: Yes. Engine diagnostics, satellite imaging, and onboard thermography often use different infrared bands, so matching the filter model to the sensor’s range is important.