Infrared filters form the core of numerous current optical setups. In areas like factory checks and heat imaging, plus lab measurements and safety gear, picking the proper wavelength band can greatly impact picture sharpness, data precision, and setup reliability. Among various choices, short wave infrared (SWIR) and long wave infrared (LWIR) filters stand out as the ones most often talked about, and yet they remain quite confusing to many.

Grasping the ways these two filter kinds function, along with the spots where each excels, allows technicians and buying groups to steer clear of expensive errors in selection. This piece explains the actual contrasts between short wave and long wave infrared filters, clarifies why selecting the wavelength counts in everyday uses, and demonstrates how Bodian Optical’s infrared filter options integrate into practical setups.

What Are the Differences Between Short Wave and Long Wave Infrared Filters?

Prior to examining uses or items, it proves useful to examine how SWIR and LWIR filters vary on a fundamental level. This separation goes beyond promotional terms. It stems from basic physics, materials used, and the manner in which infrared rays interact with items and detectors.

Short wave infrared usually points to wavelengths ranging from roughly 0.9 µm to 2.5 µm. These lengths lie near visible light, and they act in a comparable fashion. They depend on light that bounces back, not on released warmth, so outside lighting frequently comes into play.

Long wave infrared normally includes wavelengths from about 8 µm to 14 µm. Within this band, items give off rays according to their warmth levels. As a result, LWIR suits heat imaging, nighttime viewing, and detection based on warmth quite well.

In the space between these two bands, the way filters are built, the materials for coatings, and the base selections vary a lot. Such variations directly shape how well they work, how long they last, and their price.

Fundamental Principles of Infrared Filtering

Every infrared filter operates by managing which wavelengths go through and which ones get stopped. This happens mainly via thin-film interference layers placed on optical bases. For SWIR filters, the layers aim for precise edges and good passage near the visible edge. For LWIR filters, the layers need to deal with extended lengths and greater heat pressures.

Since LWIR lengths stretch further, the layer thicknesses increase, and they become more prone to physical strain and shifts in heat. That explains why long wave filters often find use in managed factory or military systems, rather than small everyday gadgets.

How Short Wave Infrared Filters Work

Short wave infrared filters let wavelengths below a set limit through, while they halt longer infrared rays. In real scenarios, this setup lets systems grab bounced infrared light, all while cutting down on warmth interference from extended lengths.

Such SWIR filters appear often in automated sight systems, chip checks, farm pictures, and laser setups. They match nicely with InGaAs detectors, which lead the SWIR sensor field because of their strong response and steady output.

Bodian Optical’s short wave pass filters, like the ISP12750 and ISP5100, aim to provide clear band division, and at the same time, they keep solid passage rates and layer toughness.

How Long Wave Infrared Filters Work

Long wave infrared filters concentrate on picking out warmth rays that items release. These filters stop shorter lengths and permit long wave infrared power to move ahead, which makes them vital for heat cameras and warmth spotting systems.

LWIR filters have to run steadily amid heat shifts, and frequently in tough surroundings. The materials and layers must stay firm without band wandering, and that is why careful building holds a key spot in LWIR filter worth.

Bodian Optical’s long wave pass filters, such as ILP10000 and ILP5500, get made for reliable warmth output in factory and detection tasks.

Why Does Wavelength Matter in Your Application?

Picking between SWIR and LWIR goes beyond what seems appealing in documents. It hinges on the planned use of the system, what the goal bounces back or gives off, and the type of setting the gear will encounter.

When the wavelength does not fit the task, it commonly results in faint signals, shaky measurements, or extra expenses from unneeded parts.

Sensitivity Requirements in IR Detection

Various wavelength bands reply to distinct physical signs. SWIR setups pick up bounced light, so their results rely a great deal on lighting setups. LWIR setups catch released warmth, which lets them function even in full dark.

Field facts indicate that SWIR pictures get used in set lighting spots like plants, where bounce variations show flaws. LWIR pictures lead in safety and watching tasks, where spotting warmth marks outweighs surface points.

Environmental and Operational Factors

SWIR lengths scatter less than visible light under some weather, like mild mist or haze. This quality renders SWIR handy for certain outside watch duties. Yet LWIR does better in pitch black and stays less bothered by sight blocks such as dark areas.

Heat span counts too. LWIR setups work finest when warmth contrasts appear. In spots where heat gaps stay small, SWIR might yield more helpful info.

Performance Impact on Imaging and Sensing Systems

The chart under shows main tech contrasts that shape setup plans and results.

| Parameter | Short Wave Infrared (SWIR) | Long Wave Infrared (LWIR) |

| Typical Wavelength Range | 0.9–2.5 µm | 8–14 µm |

| Detection Type | Reflected light | Emitted thermal radiation |

| Common Sensor Type | InGaAs | Microbolometer |

| Works in Total Darkness | No (needs illumination) | Yes |

| Typical Applications | Machine vision, inspection | Thermal imaging, security |

These contrasts make clear why choosing a filter must match the target task closely, instead of broad setup likes.

Infrared Long Wave Pass Filters From Bodian Optical

After settling on LWIR as the right band, the worth of the filter turns into the following key point. Passage steadiness, edge correctness, and layer endurance all shape the end setup outcomes.

Bodian Optical has shaped its LWIR filter range for factory and expert-level tasks, where lasting dependability holds importance.

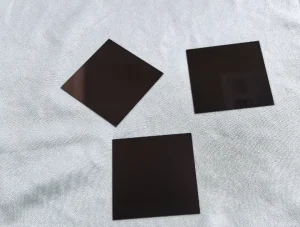

ILP10000 – Far Infrared Filtering for Thermal Systems

The ILP10000 infrared long wave pass filter gets built for tasks that call for firm passage in the far infrared area. It blocks shorter lengths well, while it keeps steady work over the LWIR band.

People often use this filter in heat imaging parts, factory warmth watch systems, and lab-level optical plans where band cleanness matters a lot. Its layer build handles heat ups and downs without clear band moves.

ILP5500 – Practical LWIR Filtering for Broad Use

The ILP5500 long wave pass filter brings a fair choice for common LWIR tasks. It gives solid edge traits, and it fits small or budget-aware systems.

This filter gets picked often for market heat cameras, built-in spotting tools, and maker projects where steady LWIR work counts, without too much tailoring.

Infrared Short Wave Pass Filters From Bodian Optical

For tasks centered on bounced infrared light, Bodian Optical’s SWIR filters stress clear band split and trustworthy layer work.

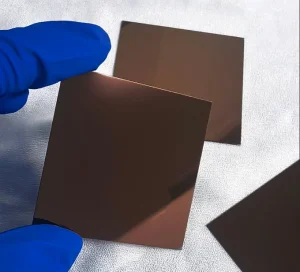

ISP12750 – High Precision Short Wave Filtering

The ISP12750 short wave pass filter suits setups that require exact length handling. It sees use in laser work, lab tools, and cutting-edge automated sight plans.

This filter cuts background buzz from longer lengths, while it holds passage high in the wanted SWIR band. Its plan backs steady linking with InGaAs detectors.

ISP5100 – Cost-Effective SWIR Filtering Solution

The ISP5100 short wave pass filter aims at tasks where solid SWIR handling fits, without driving setup prices up much. It works for usual factory pictures, check systems, and learning or market optical tools.

This type weighs output and price fairly, so it stands as a usual pick for growing projects. The match under displays how Bodian Optical’s SWIR and LWIR filters generally line up with setup wants.

| Application Type | Recommended Filter Type | Bodian Optical Model |

| Thermal Imaging | Long Wave Pass | ILP10000, ILP5500 |

| Industrial Inspection | Short Wave Pass | ISP12750, ISP5100 |

| Night Surveillance | Long Wave Pass | ILP10000 |

| Laser-Based Systems | Short Wave Pass | ISP12750 |

How to Choose Between Short Wave and Long Wave Infrared Filters

The last call frequently rests on task facts, not just theory gains. Technicians and shoppers gain from posing real questions about work conditions, detectors, and ongoing needs.

Application Scenarios and Wavelength Requirements

If the setup must spot warmth gaps, LWIR serves as the clear pick. If it must stress material gaps under set lights, SWIR typically brings sharper contrasts.

Sensor Compatibility and System Constraints

SWIR filters usually link with InGaAs detectors, whereas LWIR filters pair with warmth catchers. Blending filter kinds and detectors often brings lost output or extra setup layers.

Cost and Performance Balance

LWIR setups and filters run pricier because of material and layer needs. SWIR setups can start cheaper but might call for added light gear. Picking the fit filter soon aids in dodging redo costs down the line.

FAQ

Q1: What is the main difference between SWIR and LWIR filters?

A: SWIR filters handle bounced infrared light, and they generally require outside lighting, whereas LWIR filters spot released warmth and function in full dark.

Q2: Are LWIR filters always better for night vision?

A: For warmth spotting, yes. LWIR filters fit better for catching warmth signs at night. SWIR can manage night work too, but it needs infrared lighting.

Q3: Can Bodian Optical filters be customized for specific systems?

A: Yes. Bodian Optical offers usual types plus tailoring choices to fit exact lengths, sizes, and layer needs for maker and factory projects.