Infrared filters may seem basic. But they help today’s flame sensors spot real fire from other heat. In big factories or smart buildings, lots of things give off infrared light. Sunlight does it. Welding arcs do it. Hot machines do too. The air is full of this glow. A plain sensor would get mixed up. The filter works like a guard. It lets only the small band of infrared from flames reach the detector. That’s why these systems catch danger quick. They work well even in bright spots or busy areas.

1. Core Role: Capturing the Flame’s Unique Wavelength

Every flame has its own infrared sign. When stuff burns, it gives out light at set wavelengths. The top signal is often near 4.3 µm. That’s where carbon dioxide (CO₂) shines. An infrared filter aimed at that spot lets the sensor know it’s a real flame right away.

Keeping Out Unwanted Light

Outside or in plants, heat and bright light are everywhere. Hot metal glows. Arc welders flash. Sunlight pours in. They all send infrared. A narrow filter at 4.3 µm for the CO₂ peak blocks it all. Nothing extra hits the detector.

Some flame detectors use two paths. One has a 4.3–4.5 µm filter for flames. The other sits at 3.8 µm or 5.0 µm as a check. The system looks at both. If they rise together, it’s just heat. But if only the flame path jumps, it knows fire is there.

Very narrow filters with 90 nm width cut false alerts more. They lock tight on the flame’s key wavelength.

Matching the Fuel Type

Fuels burn in different ways in infrared. Gasoline, propane, and natural gas peak from 4.0 µm to 4.6 µm. Wood fires sit a bit lower. Hydrogen flames are weak in infrared. But they show strong in ultraviolet.

Filters get tuned for this. Some are wide. Some are narrow. They match the fuel’s band just right. It’s like giving the sensor the best ears for that fire type.

2. Teamwork: Filter and Sensor

A filter does not stand alone. It pairs with the sensor. The filter is the gate. The sensor is the heart. Each sensor type hears different wavelengths. So the filter must fit it perfect.

Pyroelectric Sensors

Pyroelectric sensors use crystals that feel heat changes. Infrared hits them. Their temp shifts a bit. That makes an electric signal.

A LiTaO₃ (lithium tantalate) detector pairs well with a 4.3 µm infrared filter. It works steady from 1 µm to 20 µm. It holds up when temps rise. The filter cuts extra light. So the sensor reacts only to CO₂ from a live flame.

Photoconductive Sensors

Another type uses PbSe (lead selenide) or PbS (lead sulfide). These change how they resist when infrared hits. PbSe feels 1–5 µm. PbS likes 1–3 µm.

Pick the right filter. Then the signal gets clean and strong. Wrong one? Extra light floods in. That brings false alarms or weak reads. Match filter to sensor’s best range. It changes everything.

3. Performance Boost: Getting a Clearer, Faster Signal

Infrared filters do more than pick wavelengths. They make the whole setup better. Good design means quicker work, steady output, and less bother from background junk.

Higher Signal-to-Noise Ratio

Cut out all but the flame band. Noise drops. Good signal stands out.

Take Bodian Optical’s 1700 nm silicon-based filter. It’s key in touchy flame detectors. It spots tiny starts that eyes miss. It grabs weak CO₂ flickers from far off.

Narrow filters with sharp cuts block almost all wrong light. The flame signal stays crisp. Even in sun or hot spots.

Wider Dynamic Range

Flames move. They flicker at 1 to 15 Hz. Now bright, now dim. Filters and sensors must keep up.

Pair with a top infrared filter. Thin-film thermoelectric sensors answer in 12 milliseconds. That’s fast to track flicker live. They handle small sparks or big blazes. No slip-ups.

4. Applications: Safety Across Industries

Infrared flame sensors with solid filters are common now. They watch over factories, gas stops, power plants, and new charge spots.

Petrochemical Facilities

Refineries, tank yards, and pipe sites use 4.3 µm filters for CO₂. They catch gas fires you can’t see. Even in day sun.

One case: A chem plant put in Bodian’s pyroelectric sensors with 4.3 µm narrow filters. Night came. A small gas leak lit up. System saw it at once. Alarm rang. Process stopped. Fire did not spread. Big save.

Power and Energy Sites

Substations, generator rooms, high-voltage spots have oil or insulators that burn. Lightning flash or arc can start it. Sensors with good filters tell lightning from fire. No fake alerts.

In one power site, the setup kicked off sprinklers seconds after real fire. It skipped harmless sparks.

New Fields

Infrared filters move to fresh spots. EV charge stations use them for battery heat or runaway. Fire stops before it grows. Auto lines watch for sparks or rub fires. Filters link with sensors and smart boxes. They make safety webs. Alerts go to rooms or cloud fast.

5. Future Path: Toward Smarter, Connected Filtering

Infrared filter making heads to smarts and links. Filters are not just coats now. They join big, wired systems.

Multispectral Fusion

New detectors mix channels. Ultraviolet, visible, infrared. They sort true fire from fakes.

A UV–IR mix uses 200–280 nm UV filter and 4.3 µm IR filter. UV sees ionized gas. IR checks CO₂. Both match? Real fire. Fakes drop way down.

IoT-Based Monitoring

Link via Internet of Things. Data flies to centers quick. Full loop: spot, warn, fix.

Bodian Optical makes IR filters for netted detectors. Coatings pass light high. Block deep. Reads stay sure. Digital talks fast.

6. Why Precision and Material Quality Matter

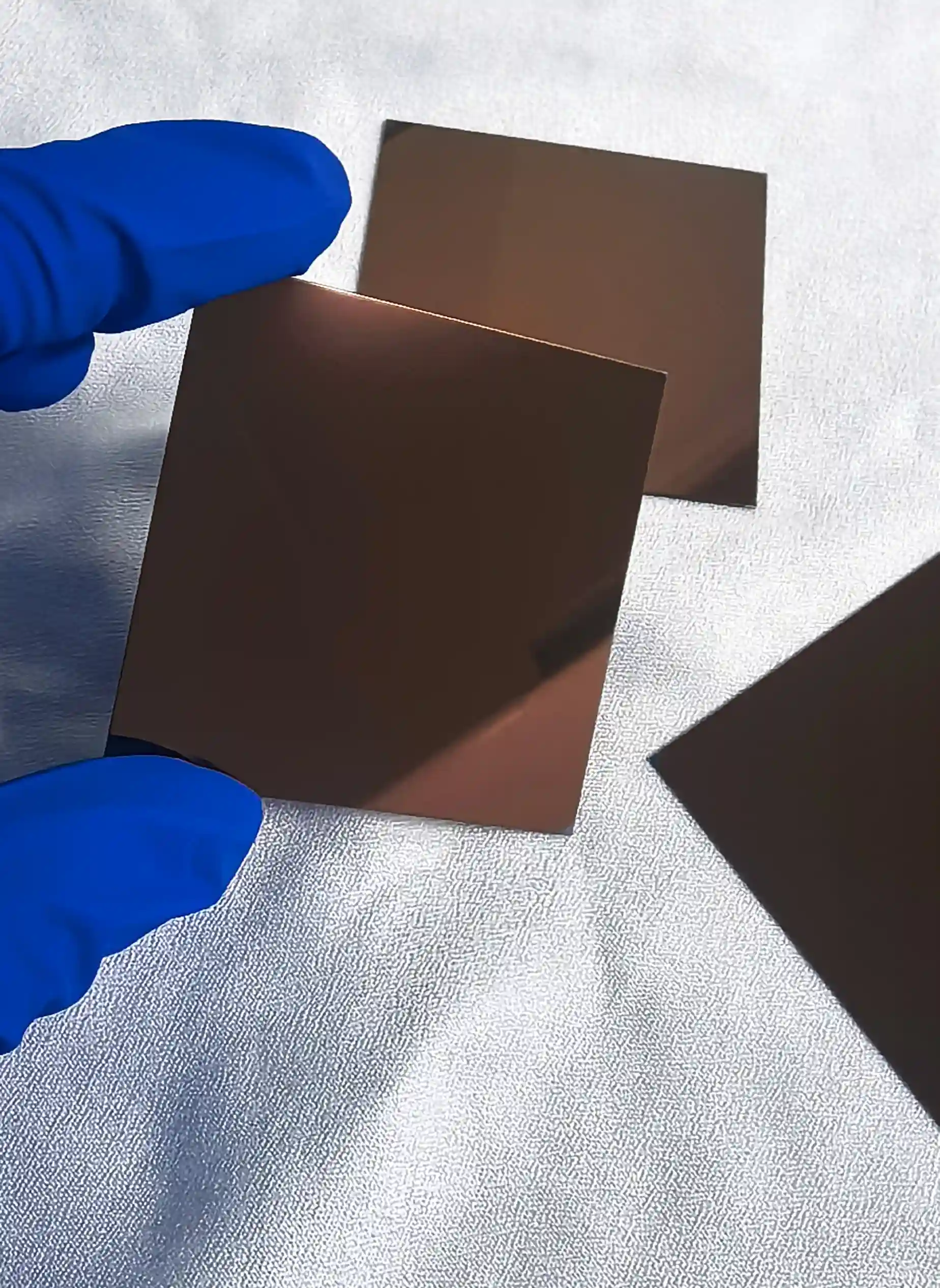

A flame detector’s power starts with its filter. Each layer—from base to coat—affects light. Tiny changes in thick or finish shift the band. Or add bounces.

Bodian Optical has over 40 years in thin-film tech. They stress tight control and good stuff. Their filters shine:

- Over 90% transmittance and blocking depth above OD6

- Custom from 1 µm to 20 µm wavelengths

- Tough bases like germanium, silicon, ZnS, and CaF₂

- Auto coating lines and tests with Agilent Cary7000 and PerkinElmer Spectrum3

These go beyond flames. Infrared thermography, lasers, gas checkers, space optics, defense. Anywhere infrared needs exact cuts. Many hold from −50 °C to 200 °C. They take wet and wild outdoors fine.

Final Thoughts

Infrared filters might be thin and almost invisible, yet they are central to modern flame detection. By choosing which wavelengths to pass and which to block, they turn messy infrared radiation into clear, useful data.

As industries grow more automated and connected, Bodian Optical continues to refine these filters—combining fine optical coating, solid materials, and smart production methods. The result is safer workplaces, quicker detection, and smarter monitoring for the world’s critical systems.

FAQs

Q1: Why is 4.3 µm so important for flame sensing?

A: It matches the top CO₂ glow from burning hydrocarbons. Clear sign that sets flames apart from hot things.

Q2: Can a single filter work for every fuel type?

A: Not quite. Fuels have their own infrared marks. Filters get made for it—4.3 µm for most hydrocarbon fires, 3.9 µm for hydrogen, or dual for tough spots.

Q3: How does the filter’s quality affect sensor life?

A: Good, heat-tough filter keeps wavelength true over time. No drift. Sensor stays tuned, even in rough spots long-term.